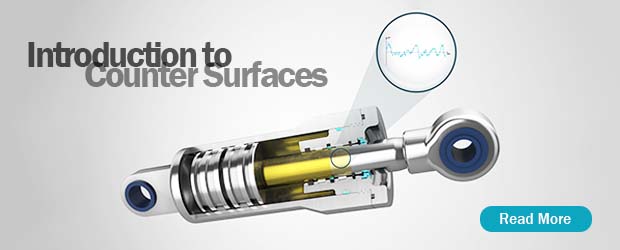

Introduction to Counter Surfaces

Traditionally piston rods in hydraulic systems were chrome plated to provide friction and surface finish characteristics. Under the REACH directive, Hexavalent Chromium (CR6) is a substance of high concern and must now be omitted from any hydraulic application, leading to the adoption of alternative coatings for the hydraulic system’s piston rods.

To maximize the performance and system life in hydraulic systems, these should be designed to optimize a system’s tribology, which is dependent on the interaction of a system’s seals, hydraulic fluid and the finish of the mating surfaces. The lubrication within the hydraulic system is fundamentally affected by the surface finish of the mating surfaces. Their characteristics will determine the lubrication within the system and therefore the tribological environment.

Traditional two dimensional representations of the piston’s surface finish were sufficient to describe chrome surfaces. The interaction between these, commonly used seals and hydraulic fluids, was well established. Currently, recommendations from seal suppliers for mating surface finishes in hydraulic systems, despite the use of alternative coatings, are still based on chrome.

However, the surface finish characteristics of alternative coatings differ significantly from chrome. To read more, click the link below to download this whitepaper. This whitepaper proposes that to fully optimize the tribology effect within hydraulic systems where alternatives to chrome are used to coat the piston rod, more in-depth recommendations should be utilized.